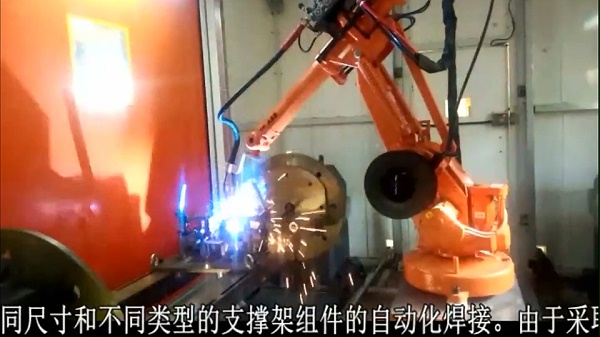

每一款設備都有市場的需求才會存在,冷焊機與氬焊機同樣如此;在薄板焊接與焊補行業,市場需求決定了選取哪種焊機;

一、氬弧焊

1、 氬弧焊只能焊1.0以上的焊絲,焊補的精確度不高;

2、氬弧焊的溫度比較高,容易變色、變形;

3、氬弧焊焊疤大,對模具的損傷比較大;

4、氬弧焊焊補模具后一般都不能上機床加工所以只能手工處理、比如銼刀挫、油石油,焊疤

大后就浪費時間了;

5、氬弧焊焊后需要熱處理,否則影響產品的使用壽命

二、冷焊機

1、冷焊機達到了激光焊的焊接、焊補精度;

2、冷焊機能準確地設定輸出電流和焊補時間,不會變色、變形;

3、冷焊機焊疤小,對模具損傷小;

4、冷焊機焊補后可以上機床加工;

5、冷焊機焊后無需熱處理,不會影響產品使用壽命。

There is a market demand for each piece of equipment. The same is true for cold welding machines and argon welding machines. In the thin plate welding and welding repair industry, market demand determines which welding machine to choose;

First, argon arc welding

1. TIG welding can only weld more than 1.0 wire, the accuracy of welding repair is not high;

2. The temperature of argon arc welding is relatively high, which is easy to discolor and deform;

3. Large argon arc welding scars cause large damage to the mold;

4. After argon arc welding and repairing the mold, it can not be processed on the machine tool, so it can only be handled manually, such as file cutting, oil and petroleum, welding scars.

Wasted time

5. After TIG welding, heat treatment is needed, otherwise it will affect the service life of the product.

Second, cold welding machine

1. The cold welding machine has achieved laser welding and welding repair accuracy;

2. The cold welding machine can accurately set the output current and welding repair time without discoloration or deformation;

3. Cold welding machine has less welding scars and less damage to the mold;

4. Cold welding machine can be machined after welding repair;

5. The cold welding machine does not require heat treatment after welding, and will not affect the service life of the product.